RESISTANCE

The products of Better Basics Laborbedarf use components made of polyamide-12 (PA12) in the selective laser sintering process (SLS-3D printing) as well as metal parts powder-coated with plastic. Both processes deliver long-term UV-resistant components-

Example of a UV test, arrangement for photographic illustration, not a scientific test setup.

Resistance to UV light and aggressive media

General information on UV resistance

The products of Better Basics Laborbedarf use components made of polyamide-12 (PA12) in the selective laser sintering process (SLS-3D printing) as well as metal parts powder-coated with plastic. Both processes deliver long-term UV-resistant components.

The products of Better Basics Laborbedarf use components made of polyamide-12 (PA12) in the selective laser sintering process (SLS-3D printing) as well as metal parts powder-coated with plastic. Both processes deliver long-term UV-resistant components.

Dr. Sebastian Stein, Production Manager

Polyamide-12 (PA12) components made by the selective laser sintering process (SLS)

PA12 is an extremely resistant polymer with very good weathering resistance. Weathering tests (ISO-4892-2) have shown that even after 10 years of continuous outdoor use, there is no reduction in the tensile strength of test specimens made of PA12.

PA12 components from the SLS process are dyed green by Better Basics Laborbedarf before use in the laboratory. To protect the colour from fading, the components are treated in a second step with a UV-absorbing protective agent from the industrial sector. This absorbs radiation in the UV range very effectively and thus protects both the dye and the underlying component.

Figure 1: Absorption spectrum UV treatment agent PA12-SLS components

Weathering tests (ISO 11507) have shown that PA12 components treated with the UV protection agent have not shown any decrease in colour intensity after 500 hours of UV radiation exposure. It can therefore be assumed that the UV protection is very effective.

In a third step, the coloured PA12-SLS components are infiltrated with a protective polymer layer. This protects both the colour and the UV protective layer from detachment on contact with solvents and provides additional protection for the component.

Figure 2: 3-level protection for PA12 components at Better Basics Laborbedarf

Powder-coated metal components

The metal components used by Better Basics Laborbedarf are protected from corrosive environmental conditions by means of powder coating. Depending on the application, polyester or epoxy powder coatings are used, which are known for their high resistance to weathering and chemicals.

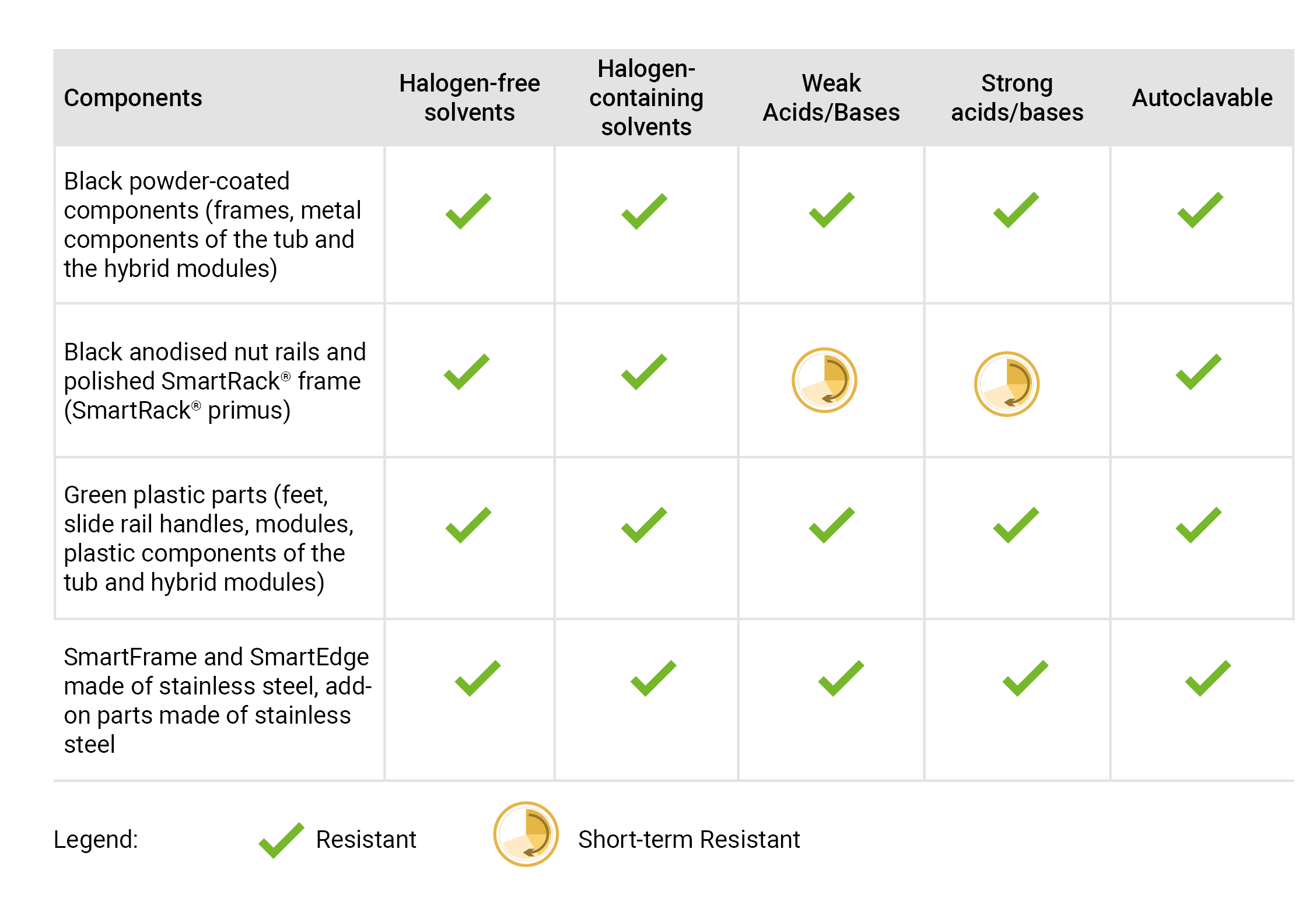

Resistance of the SmartRack® to aggressive media

The SmartRack® consists of a frame, the slot rails and modules suspended in the slot rails. Three different types of materials are used in the SmartRack®:

- Black powder-coated aluminium parts (frames, metal components of the tub and the hybrid modules)

These components are aluminium parts, which are protected by a powder coating of epoxy resin. The powder coating is stable against a large number of halogenated and halogen-free solvents from the laboratory sector. However, prolonged exposure of the solvents to the powder coating should be avoided. The powder coating is stable against contact with acids/bases. The components are completely autoclavable.

- Black anodised slotted rails and polished SmartRack® frame (SmartRack® primus)

The slot rails are black anodised aluminium components and the SmartRack® primus frame is polished aluminium. Both are resistant to halogenated and non-halogenated solvents. Aggressive acids/bases can damage the anodised layer or the surface of the SmartRack® primus. The elements are fully autoclavable. To gently clean the anodised aluminium slotted rail or the SmartRack® primus frame, we recommend using a pH neutral, odourless hand cleanser. Ensure that the hand wash is odourless and contains no perfumes, greases or additives. Clean the parts by hand and rinse thoroughly under clean water.

- Green plastic parts (feet, slide rail handles, modules, plastic components of the tub and hybrid modules)

These components are 3D-printed (laser-sintered) components made from the high-performance plastic polyamide-12 (PA12). The components are stable to halogenated and halogen-free solvents such as, for example, chloroform, dichloromethane, chlorobenzene, hexane, methanol, ethanol, acetone, ethyl acetate and toluene. The components are stable to most acids and bases, but concentrated acids such as concentrated nitric and sulfuric acid lead to damage to the components during prolonged exposure. After prolonged exposure to aggressive media, discolouration of the components may occur, but this is only superficial and does not limit their functionality. The components are completely autoclavable.

- Stainless steel parts (stainless steel frame, stainless steel L-profiles of the SmartEdge, stainless steel components of some SmartRail models)

These components are made of high-quality stainless steel (e.g. V2A/1.4301 or V4A/1.4401) and are characterised by their excellent corrosion resistance. Stainless steel is resistant to a wide range of aggressive media, including halogenated and halogen-free solvents as well as strong acids and bases.

Resistance:

- Solvents: The stainless steel parts are resistant to organic solvents such as chloroform, dichloromethane, chlorobenzene, hexane, methanol, ethanol, acetone, ethyl acetate and toluene.

- Acids and bases: They are resistant to most acids and bases, even in concentrated form. Exceptions are particularly aggressive media such as concentrated hydrochloric acid or hydrofluoric acid, which can attack the surface.

Cleaning and care: The stainless steel components are fully autoclavable and are therefore ideal for sterile applications. We recommend mild cleaning agents for cleaning. Avoid aggressive, chloride-containing cleaning agents, as high chloride concentrations can damage the passive layer of the stainless steel and promote corrosion. After cleaning, rinse the components thoroughly with clean water and dry them carefully to avoid water stains or corrosion.

Due to its good resistance to most aggressive media in the laboratory, the SmartRack® is well equipped for use in everyday laboratory life, as most contaminations are short-lived and are eliminated immediately for the purpose of proper occupational safety. If prolonged exposure to aggressive media occurs, the component surface may become discoloured, although this will not affect the functionality of the components. In addition, due to the modularity of the SmartRack®, it is always possible to replace individual modules or components if necessary.

Dr. Sebastian Stein, Production Manager

Overview of the resistance of the SmartRack® and the SmartIntegrate products to aggressive media

If you have any further questions, please contact us at: contact@better-basics.de

Further information

You can download our product catalog as a PDF file from the downloads section of our website.

If you are interested in our products, please use the inquiry form in the downloads section.