30% EFICIENCY IMPROVEMENT BY IMPLEMENTING SMARTRACK® IN PHARMACEUTICAL QUALITY CONTROL

This study aimed to evaluate the impact of implementing the SmartRack® laboratory organisation system on extracting active pharmaceutical ingredients. The objective was to verify a 30% efficiency improvement with the use of SmartRack® in three experimental phases: preparation, execution and breakdown.

30% Efficiency Improvement by Implementing the SmartRack® and the innovative solutions of the SmartIntegrate product line in Pharmaceutical Quality Control

Abstract:

This study aimed to evaluate the impact of implementing the SmartRack® organisation system and the innovative solutions of the SmartIntegrate product line laboratory on extracting active pharmaceutical ingredients. The objective was to verify a 30% efficiency improvement with the use of SmartRack® and the innovative solutions of the SmartIntegrate product line in three experimental phases: preparation, execution and breakdown.

Systematic modelling of the extraction of active pharmaceutical ingredients

Quality control in pharmacy is essential to ensure that pharmaceutical products meet the highest standards. It guarantees the efficacy, safety and purity of medicines to protect the health and well-being of patients. Rigorous quality assurance measures ensure that pharmaceutical products are consistent and reliable. These measures include analysis of the quality and quantity of active ingredients in the final product.

With the increasing complexity and diversity of products, the quality control requirements for already high standard laboratories and personnel are becoming more complex. This is particularly true for highly specialised products. In order to achieve comprehensive test coverage with efficient resource management, the SmartRack® organisational system and the innovative solutions of the SmartIntegrate product line were investigated for their efficiency-enhancing properties.

Methodology

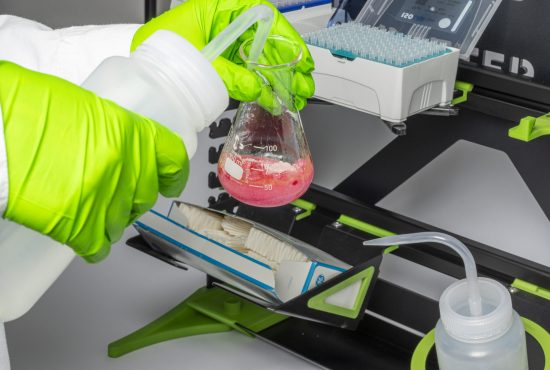

The quantification of active ingredients, in particular the sample preparation of a standard powder tablet, was demonstrated as an example. The experimental procedure was compared with and without the implementation of SmartRack® and the innovative solutions of the SmartIntegrate product line. The sample was crushed, ground and the fillers were extracted by shaking for separation. The focus of the comparison was on the efficiency improvement and standardisation of the experiments through the use of the SmartRack® laboratory organisation system and the innovative solutions of the SmartIntegrate product line.

Comparison of procedures with and without SmartRack®

The grinding and distribution of powder tablets into tubes for multiple determinations was much more efficient and comprehensive with pre-sorted and securely stored tubes in SmartRack® directly at the workstation. In addition, the solvent for the slurry was available on site. Rapid filtration benefited from the immediate availability of filters and water at the workstation. The risk of accidents and errors during phase separation was minimised by secure holders for separation funnels and the organisation of glassware in the rack. The ergonomic benefits and improved clarity provided by the SmartRack® and the innovative solutions of the SmartIntegrate product line facilitated pipetting into well plates. This encouraged time-optimised, consistent execution of the experiment.

The lack of storage for samples, equipment and materials resulted in additional walking and searching. There was no set order for the work materials, and the result was a prolonged turnaround time due to non-standardised procedures. Manually setting up the separating funnel stands took more time than selecting the appropriate module and clicking it into the SmartRack® or one of the innovative solutions of the SmartIntegrate product line. Workspace occupation was significantly higher due to the traditional setup. This made it difficult to perform or prepare for subsequent experiments. Errors or contamination were facilitated by a lack of overview.

Conclusion

The SmartRack® system and the innovative solutions of the SmartIntegrate product line significantly improve the organisation and efficiency of sample preparation for drug assays in pharmaceutical quality control. By optimising the workspace and reducing sources of error, the SmartRack® and the innovative solutions of the SmartIntegrate product line support precise and reliable execution of pharmaceutical experiments. The comparative experiment with the SmartRack® and the innovative solutions of the SmartIntegrate product line suggest that efficiency can be increased by 30%. The results underline the importance of innovative organisational systems to improve the quality of pharmaceutical experiments.

Download our folder on the topic here

Information on 30% Efficiency Improvement by Implementing the SmartRack® and the innovative solutions of the SmartIntegrate product line in Pharmaceutical Quality Control

Further Information

You can download our product catalog as a PDF file from the downloads section of our website.

If you are interested in our products, please use the inquiry form in the downloads section.