LEAN MANAGEMENT AND INCREASING EFFICIENCY BY USINF THE SMARTRACK®

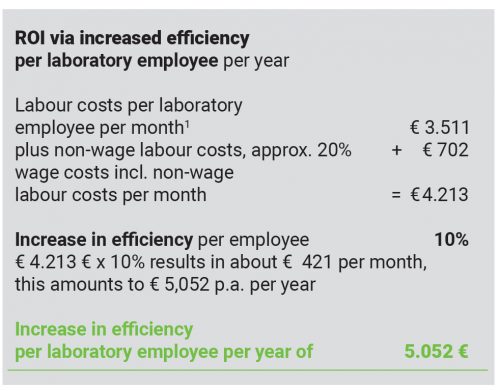

Creating value without waste: 10% increase in efficiency in the laboratory when using the SmartRack®.

By using the SmartRack®, an increase in efficiency of up to 10% is achieved by optimising working hours during the test execution as well as during assembly, disassembly and cleaning.

The SmartRack® is therefore the ideal system for supporting LEAN management models in laboratories.

LEAN Management and increasing efficiency by using the SmartRack® and the innovative solutions of the SmartIntegrate product line

Creating value without waste: 30% increase in efficiency in the laboratory when using the SmartRack® and the innovative solutions of the SmartIntegrate product line

By using the SmartRack and the innovative solutions of the SmartIntegrate product line, an increase in efficiency of up to 30% is achieved by optimising working hours during the test execution as well as during assembly, disassembly and cleaning

The SmartRack and the innovative solutions of the SmartIntegrate product line are therefore the ideal systems for supporting LEAN management models in laboratories

How can an increase in efficiency of up to 30% be achieved by using the SmartRack® and the innovative solutions of the SmartIntegrate product line?

The SmartRack® and the innovative solutions of the SmartIntegrate product line increase efficiency both directly and indirectly, because increasing efficiency and saving space are mutually reinforcing. 30% more efficiency at the laboratory workstation and 80% space savings mean more employees who can work in the laboratory at the same time or more free workspace which can be used by the existing employees, who in turn can carry out more laboratory work per working day. Laboratory work is basically divided into four work steps:

- assembly, disassembly and cleaning of the test set-up

- test execution

- personal allowance time

- secondary activities.

The SmartRack® and the innovative solutions of the SmartIntegrate product line allow a larger number of sample vessels, (laboratory) work equipment and consumables to be stored directly at the laboratory workstation. This allows significantly more tests or analyses to be carried out. The potential of increasing efficiency in the work areas of test execution as well as assembly, disassembly and cleaning is explained by the following examples:

During the test execution:

- Error rates are reduced through greater clarity and a standardisation of the workstation

- Samples can be temporarily stored in a space-saving manner and in a structured arrangement, which reduces the risk of confusion

- One-hand operability is possible, which increases occupational safety and ensures greater effectiveness, so that tests do not have to be interrupted

- All the work equipment is located directly at the workstation (e.g. boxes for gloves or tissues, as well as glassware or other work equipment)

- Work equipment is stored more safely hung up than lying down, since no contamination by liquids can occur while hung up (e.g. tipping over of e.g. round flasks is not possible, contamination of pipettes etc. does not occur)

- If additional space is required at short notice in a laboratory fume hood, on a laboratory table or in a safety workbench for test execution, the SmartRack® and the innovative solutions of the SmartIntegrate product line and the samples and equipment temporarily stored in it can be easily removed or taken down and placed somewhere else.

During assembly, disassembly and cleaning:

- There are no walking distances, as more consumables are already available directly at the workspace

- There is a better overview of the available work equipment, because you can immediately tell from a visual inspection whether work equipment, consumables or glassware are missing or need to be reordered

- Search times are also reduced thanks to the clear arrangement in the SmartRack® and the innovative solutions of the SmartIntegrate product line wird die Arbeitsfläche frei. Damit kann viel Zeit bei der Reinigung des Arbeitsplatzes gespart werden.

Modern laboratory environment: The SmartRack® together with digital and electronic laboratory equipment and work equipment

Increasing the efficiency of the test execution using the example of column chromatography:

- A chromatography column is installed in a SmartRack® or one of the innovative solutions of the SmartIntegrate product line with 2 chromatography column holders.

- In addition, numerous round flasks of the NS29 type are hanging in the same product.

- With the round flasks, the fractions separated in the column are collected, while the flasks can be removed and hung up with one hand, without the flow of the column having to be interrupted when changing the flasks.

- The round flasks are secured in the SmartRack® and in the innovative solutions of the SmartIntegrate product line in a way which prevents them from tipping over, and one after the other in a way which prevents them from being confused, and are safely stored temporarily.

Increasing efficiency using the example of the standardisation of test setups:

- A test can be set up in a standardised way in the SmartRack® or one of the innovative solutions of the SmartIntegrate product line and can therefore be repeated under comparable conditions.

- Guidelines for the optimal test setup can thus be specified by the laboratory manager and the occupational safety officer and safely adhered to during the test execution.

- Error-prone individual solutions in the test setup are eliminated and the risks of a failed test are greatly reduced

- Once developed, standardised test setups for a laboratory can be replicated, which saves time, since the knowledge required for optimal implementation can be recorded in a defined form and communicated on.

Example of the safe handling of pipettes and pipette tip boxes in a sterile workbench:

- Pipettes and pipette tip boxes are hanging in a SmartRack® mini.

- Due to the hanging storage, the work surface can be kept constantly sterile.

- If the pipette is stored hanging, its tip cannot be contaminated by it being put down.

- In the event of an accident, the work equipment and samples are hanging “on top” in the SmartRack® mini and are not contaminated “at the bottom” on the work surface.

1: Laboratory employees in Germany receive an average monthly salary of € 3,511. Of course, significantly higher salaries are also possible and not uncommon. As of: January 2023. Source: www.gehalt.de/einkommen/suche/labor-mitarbeiter

Conclusion: The SmartRack® and the innovative solutions of the SmartIntegrate product line increase the efficiency of the laboratory staff and already pay back their investment costs in the first year of use.

This significantly increases the productive working time per laboratory employee and per laboratory workstation. Multiple burdens, such as those caused by the handling of unstructured vessels which have been set aside, are also eliminated. This leads to an increase in efficiency of the laboratory staff of up to 30%.

For the first time, lean management and quality management systems such as 5S can be implemented and applied concretely in the laboratory environment with the SmartRack® and the innovative solutions of the SmartIntegrate product line:

The SmartRack® and the innovative solutions of the SmartIntegrate product line make it possible to achieve and secure increased process quality with increased efficiency and improved productivity at lower costs in the long term. The SmartRack® and the innovative solutions of the SmartIntegrate product line guarantee more order and cleanliness at the workstation and changes behaviour at the laboratory workstation.

Download our folder on the topic here

Information on LEAN Management and increasing efficiency by using the SmartRack® and the innovative solutions of the SmartIntegrate product line

Further information

You can download our product catalog as a PDF file from the downloads section of our website.

If you are interested in our products, please use the inquiry form in the downloads section.