FAILURE PREVENTION STRATEGIES AND MANAGEMENT METHODS

At a time when global competitive pressures and economic constraints are forcing companies to constantly adapt and improve, failure prevention strategies have become indispensable tools. Originally motivated by the Industrial Revolution, when quality and efficiency in mass production became critical factors, the need for these strategies has increased with the globalisation and technological advances of the 20th century.

Failure prevention in the laboratory:

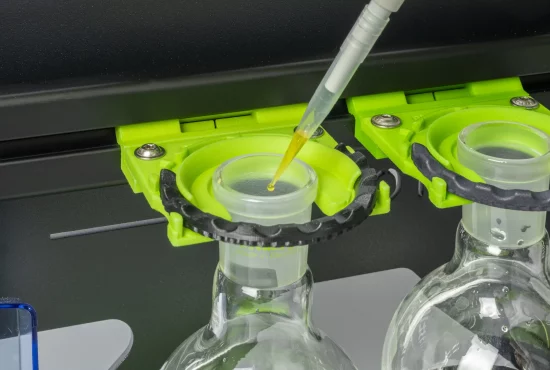

SmartRack® and the innovative solutions of the SmartIntegrate product line ensure safety and failure prevention

The importance of error prevention strategies under competitive pressure

At a time when global competitive pressures and economic constraints are forcing companies to constantly adapt and improve, error prevention strategies have become indispensable tools. Initially motivated by the Industrial Revolution, when quality and efficiency became critical factors in mass production, the need for these strategies intensified with globalisation and technological advances in the 20th century. Competition in markets led to higher customer expectations, demanding unprecedented quality and efficiency from companies. These economic pressures encouraged the development of management methods such as Lean Management and Six Sigma, which aim to reduce waste and maximise process quality. From the early days of Taylorism to today’s comprehensive quality assurance programmes, defect prevention strategies reflect the drive to remain competitive through continuous improvement and adaptation. In today’s business environment, these strategies are not just a means of reducing defects; they are essential for companies that want to succeed in a highly competitive environment by fostering innovation and embedding continuous improvement as part of their corporate culture.

How does the SmartRack® and the innovative solutions of the SmartIntegrate product line specifically help in the application of various error prevention strategies in the laboratory?

Lean Management and the SmartRack ® and the innovative solutions of the SmartIntegrate product line:

Lean Management focuses on minimising waste to maximise efficiency. This includes unnecessary inventory, unnecessary movement and waiting time. The key to Lean Management is the continuous search for improvements in workflow. The SmartRack® and the innovative solutions of the SmartIntegrate product line play a key role in this, as their modular and adaptable structure allows laboratory equipment and materials to be placed exactly where they are needed. This reduces unnecessary movement and optimises accessibility, promoting more efficient use of working time and resources. By creating an order with clearly defined locations for each tool and sample, the SmartRack® and the innovative solutions of the SmartIntegrate product line significantly reduce the likelihood of delays and errors.

Total Quality Management (TQM) and the SmartRack® and the innovative solutions of the SmartIntegrate product line:

TQM is a comprehensive system that places quality at the heart of all business processes. It emphasises that everyone in the company, from management to employees, contributes to quality. A key aspect of TQM is the principle of error prevention rather than error correction. The SmartRack® and the innovative solutions of the SmartIntegrate product line support this approach by creating a structured and error-proof environment. The intuitive organisation and labelling of storage spaces in the SmartRack® and the innovative solutions of the SmartIntegrate product line system facilitates the correct storage and handling of laboratory equipment and consumables, helping to maintain quality standards and prevent cross-contamination.

Klassischer, sehr unordentlicher Laborarbeitsplatz im Vergleich zu einem…

Six Sigma and the SmartRack® and the innovative solutions of the SmartIntegrate product line:

Six Sigma aims to improve process performance by reducing variability in business and manufacturing processes. It uses data-driven techniques and quality management tools to minimise defects and improve process efficiency. The SmartRack® and the innovative solutions of the SmartIntegrate product line contribute to the Six Sigma methodology by enabling standardised organisation of work materials to support consistent process execution. By reducing variability in daily laboratory operations, such as standardised storage and easy access to frequently used reagents and equipment, the SmartRack® and the innovative solutions of the SmartIntegrate product line directly contribute to maximising efficiency.

Poka-Yoke (error proofing) and the SmartRack® and the innovative solutions of the SmartIntegrate product line:

Poka-Yoke aims to prevent errors through the design of products and processes. By incorporating simple but effective safety mechanisms, errors are avoided before they can occur. The system of the SmartRack® and of the innovative solutions of the SmartIntegrate product line utilise this approach by designing features that facilitate correct use of the system and prevent errors. Accurate labelling and process-oriented module layout ensure that the correct equipment and materials are used. Clear storage prevents incorrect purchases or shortages. The clear overview is particularly helpful during shift changes or when experiments need to be continued. Despite changes in personnel, the experiment remains reproducible and comparable. Deviations are proactively prevented, and problems that arise can be quickly and easily resolved using the modularity of the SmartRack® and the innovative solutions of the SmartIntegrate product line.

Kaizen (Continuous Improvement) and the SmartRack® and the innovative solutions of the SmartIntegrate product line:

Kaizen promotes continuous, incremental improvement of processes through the involvement and contributions of all employees. This approach fosters a culture where suggestions for improvement are valued and implemented. The SmartRack® and the innovative solutions of the SmartIntegrate product line are an ideal tool for implementing Kaizen in the laboratory as they offer flexible and adaptable solutions that can be easily modified to continuously improve efficiency and safety. Through its modularity, the SmartRack® and the innovative solutions of the SmartIntegrate product line can be quickly adapted to changing quality requirements, new products or innovative working methods, fostering a culture of continuous improvement.

4D Management Method and the SmartRack® and the innovative solutions of the SmartIntegrate product line:

The 4D management method, focusing on the phases Define, Design, Develop, and Deploy, emphasizes the importance of error analysis and the resulting organizational adjustments. A key instrument within this methodology is the so-called 4D report. It serves to document errors that have occurred in detail, analyze them, and define measures to prevent these errors in the future. The strength of the SmartRack® and the innovative solutions of the SmartIntegrate product line lay in offering a unique workplace organization system for laboratory workplaces, enabling workflow restructuring and optimization according to insights from the 4D report. Their modular and flexible design allows the SmartRack® and the innovative solutions of the SmartIntegrate product line to adapt the laboratory environment specifically to the needs and challenges of the respective laboratory. Thus, the SmartRack® and the innovative solutions of the SmartIntegrate product line not only support efficient use of available space but also represents one of the most important optimization measures in error analysis. In this sense, the SmartRack® and the innovative solutions of the SmartIntegrate product line enable sustainable improvement of laboratory work by immediately implementing the principles of the 4D management method, thus contributing to a continuous increase in efficiency and safety in the laboratory.

The 8D concept and the SmartRack® and the innovative solutions of the SmartIntegrate product line :

The 8D concept defines a precise sequence of steps with corrective actions to completely and permanently prevent a process deviation. Interdisciplinary teamwork is used to precisely define the problem and verify its causes. Appropriate measures are then selected, implemented and integrated into the process. In the laboratory in particular, the safety of employees and the validity of results are of the utmost importance. Incorrect measurements must be repeated immediately with new tests and avoided on the next day of analysis. The integration of the SmartRack® and the innovative solutions of the SmartIntegrate product line are a technical preventive measure. Permanently installed at the workstation and adapted to the process, they provide a flexible, complete solution for avoiding errors in complex laboratory tests.

Summary: Why the SmartRack® and the innovative solutions of the SmartIntegrate product line also belong in your laboratory

In an era where quality and efficiency are paramount in the face of global competition, the SmartRack® and the innovative solutions of the SmartIntegrate product line have established themself as an essential tool for error prevention in laboratories. By integrating proven error prevention strategies such as Lean Management, Total Quality Management (TQM), Six Sigma, Poka-Yoke and the 4D concept, the SmartRack® and the innovative solutions of the SmartIntegrate product line offer a modular and adaptable solution that optimises workflows and minimises susceptibility to errors. They increase laboratory safety and efficiency by providing a structured, error-free environment, helping laboratories to meet today’s high demands for quality and efficiency. The SmartRack® and the innovative solutions of the SmartIntegrate product line revolutionise the way laboratories organise their workspace and make a significant contribution to sustainable error prevention and process efficiency.

Further information

You can download our product catalog as a PDF file from the downloads section of our website.

If you are interested in our products, please use the inquiry form in the downloads section.